There is an old woodworkers saying that one can never have enough clamps.

So, what clamps do I need for woodworking? If you are new to woodworking, you have probably gone to a shop and left more confused than ever by the huge variety of tools. Just the wide array of clamps arranged neatly in rows can indeed get confusing.

The good news is, you do not need all of them to begin your woodwork project. You can start with a few and grow your collection as you gain competency and the confidence to take on larger or more intricate projects.

What are Clamps?

Clamps are fastening devices used to hold wood pieces together to prevent separation and movement. They can also hold planks of wood steady for drilling, filing, sawing, chiseling, and painting.

Generally, clamps have a moveable jaw attached to an adjustable screw.

So, What Clamps Do I Need for Woodworking?

A woodworker complaining about having too many clamps is almost unheard of. While having many is good, having the right clamps, and knowing how to use them is definitely better.

Still, as versatile as some clamps are, they cannot serve every function.

Here are the most common clamps and their functions.

Trigger Activated Bar Clamp

This clamp’s bar length ranges from 6” to 50”. It can be operated with one hand, freeing up the other hand to hold workpieces or maneuver around the workbench.

As its name suggested, the trigger clamps used a trigger mechanism to adjust its jaws. It is also called the one handed bar clamp because it allows for one handed operation.

This clamp is ideal for both light and heavy woodwork duty. It’s also easy to manure, making it the go-to clamp for both professionals and armatures.

Aside from clamping, some trigger clamps come with detachable jaws that can be placed on the main bar facing different directions. In this setting, the clamp can be used for detaching.

G/C Clamp

This clamp looks like an upper Case letter G, which is where it gets its name from. It’s also known as the C-clamp.

The G/C clamp is very versatile and is an essential must-have when working with a restrictive budget. Different styles of G/C clamps come with throats of varying depths, the general range being 3’’ to 14’’.

There are also miniature versions at 1’’ by 1’’. These are often for people taking up woodwork as a hobby, however.

In a workshop, these clamps work best on narrow pieces of wood where one requires to apply a lot of pressure on multiple points.

Spring Clamps

The spring clamp is also called the pinch clamp. This tool features two handles, two grippers, and a spring pivot to connect all the moving bits.

These apply light clamping pressure. You apply force to the handled to release the pressure and hold.

The jaws are fitted with rubber pads or other soft padding to prevent damage to the item being clamped.

These are great for domestic use and for holding smaller, more delicate bits when woodworking.

F Clamps

This F-shaped clamp has a long vertical bar fitted with two perpendicular bars. The F-clamp is very sturdy and can be used for heavy woodworking.

You can find it in different sizes depending on the bulk of the wood pieces you will be using.

These clamps are available in numerous sizes. You can therefore get the idea-sized pump for the job you intend to carry out. These can go from 6” to 48”.

Parallel Jaw Clamp

The parallel clamp is much like the F-clamp, only much more powerful.

Just like the F clamp, the parallel clamp allows for wide openings. The jaws of this clamp remain parallel when packed with increasing loads. This prevents dimpling and offers a larger distribution area.

This parallel clamp can deliver about 1000 pounds of pressure. This clamp is often the preferred clamp for large glue-up jobs.

Aside from their power, these clamps are also very versatile. Their downside is that they tend to be expensive, which is expected for the level of power and the versatility they deliver.

These clamps also come with large throats that comfortably hold 3 to 4 inches of material.

A parallel jaw clamp is easy to disassemble as well, and you can turn it around to functions as a spreader.

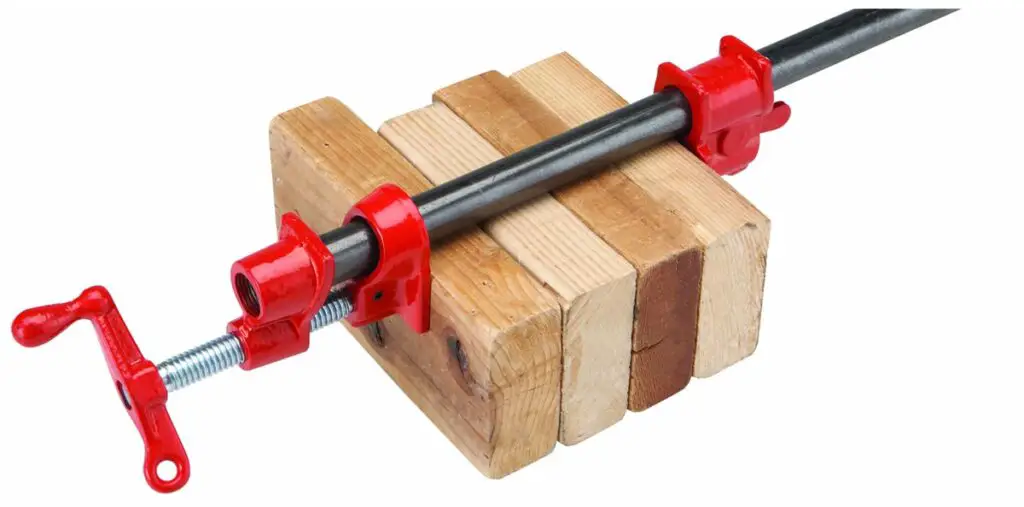

Pipe Clamps

These are heavy-duty reasonably-priced clamps. Most people get flustered by their relatively small clamping mechanism.

Once you pick your required size, you need to purchase steel gas pipes from your hardware store. You then need to slide the clamp into the pipes to have a functional clamp.

The pipe’s thickness remains standard at ½” or ¾”. However, you can buy pipes of different lengths depending on the lengths you require for individual projects.

A downside to the pipe clamp is the throat, which is often short and limiting for certain woodwork tasks.

Another negative aspect of this clamp is that the pipers tend to leave residue and grease from the pipes to the project one is working on. However, you can place rags between the pipes and your wood pieces to prevent the residue transfer.

Quick Tips for Working with Clamps

As mentioned earlier, knowing how to use clamps is just as important as buying the correct ones.

1. Work on a flat surface

Despite your best efforts, an assembly table that is not entirely flat can destabilize your clamp and cause racking and twisting. You then end up with a less than perfect finished result.

2. Apply pressure evenly

Use enough pressure to bring two pieces together along the glued edges. You should see some squeeze out without squeezing out all the glue applied.

Equal squeeze out along the joint line is one way to let you know you are applying even pressure.

3. Create Barriers

Dents and stains are a common complaint when using clamps. Whenever you are using a clamp without protective padding, place a piece of waxed paper between the workpiece and the clamp.

This prevents glue from sticking onto the clamps’ surface. Thin scrapes of softwood can similarly be used to prevent marring or denting.

The Woodworkers Guild of America has an excellent series on how to glue and clamp wood properly. For example here is a quick video about how to clamp irregularly shaped objects.

So in the end when you asked ‘What Clamps Do I Need For Woodworking?’

The answer is ‘It depends on the job’.

As you get more experienced and take on new projects your collection of clamps will inevitably grow. Old woodworkers all have massive collections of clamps for good reason, and now you understand why!