The grind is essentially the heart of a blade.

In other words, it refers to the manner in which a blade is cut to ready it for sharpening and polishing. The grind is the functioning part of your knife for most of its jobs and determines how well the knife will cut and even retain sharpness.

There are many kinds of grinds out there, including the hollow grind, full flat grind, chisel grind, sabre grind, convex grind, and scandi grind. Of course, all of these types of edges come with their own unique features, but in this piece, we’re going to take a more detailed look at a hollow grind.

Understanding a hollow grind

As the name already suggests, a hollow grind is actually hollow. It’s quite a common grind for many knife blades. Blades with a hollow grind offer great cutting qualities and more flexibility than blades with other types of grind.

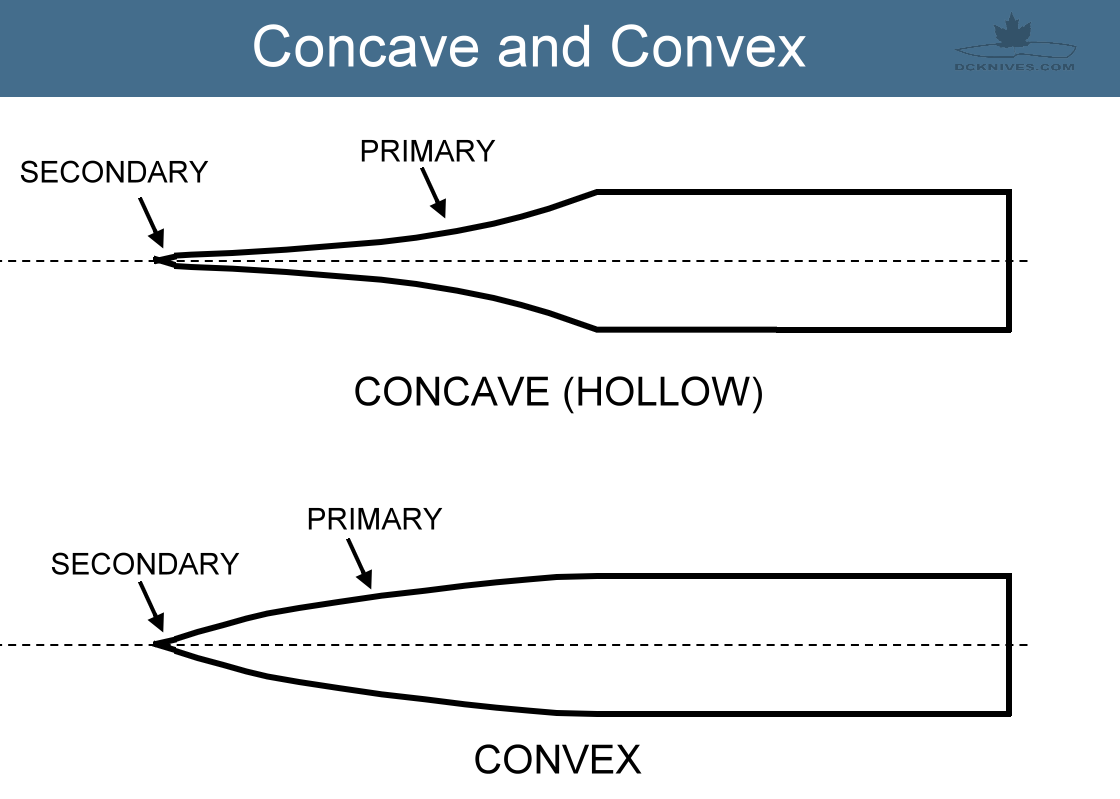

A hollow ground knife blade is one that’s been ground to create a distinct bevelled, concave edge along the knife’s cutting edge. This effect is achieved by having the grind start below the middle of the knife, producing a small concave wedge that’s very sharp and easy to maintain. Many mass-produced knives have hollow ground blades, as they’re also easy to manufacture and customers prefer knives that are easy to sharpen.

When making a hollow ground blade, a grinding wheel cuts a convex scoop from the blade. The knife’s cutting edge is found at the base of the scoop, and it’s very fine and therefore extremely sharp.

In cross section view, the blade almost looks like an old-school fountain pen nib, with a soft, fluted base and strong upper section. The secondary bevel is easily gripped with a sharpening stone, making sharpening super easy.

dcknives.blogspot.com

Hollow grind blades are perfect for soft, thin materials. They shouldn’t be used for tough materials with larger diameters. Hollow ground blades were traditionally used for scissors and straight razors. Today, this blade type is mainly found in kitchen knives, as well as outdoor and hunting knives.

If you want your knife to slice really well, but don’t want it to get too deep, a hollow grind will do the job superbly. Dressing your game needs a knife with excellent slicing to take off the skin. For this reason, hollow ground blades are common on hunting as well as skinning knives.

Picking a hollow ground blade

When selecting a knife, you should go for one with a strong blade made from a high-quality metal. If you can, go to the store personally so you can pick up the knife and see how it feels.

Make sure the handle feels comfortable in your hand and the knife is balanced when held. An awkward, cumbersome blade won’t be fun or easy to work with.

TIP: You shouldn’t run your knives through the dishwasher because that can make them dull. Instead, hand wash your knives and always wipe them dry to maintain the blades.

Of course, a hollow grind isn’t without downsides. The thinner edge may roll over or chip with hard use. Also, it can have trouble cutting food owing to the concave scoops taken out of the blade. These hollowed out parts can create suction on occasion, making deep cuts a bit harder.

How to sharpen a hollow ground blade

You can sharpen a hollow ground with ease.

Straight razors have a hollow grind. They’ve always been sharpened on a leather strop, with the help of abrasive stropping compound. The majority of hollow grind knives made today feature a secondary V-shaped bevel at the cutting edge. Therefore, they can be sharpened with a sharpening stone, or with a sharpening system. A hollow-ground knife can be incredibly sharp, but it can greatly benefit from a bit of stropping.

Sharpening the edge of your knife with a grinding wheel will produce a hollow grind. As there’s little material behind the edge, it’s less durable (although how long the edge can last is debatable).

See how a freehand hollow grind is done rather quickly after a bit of practice.

A straight razor (for shaving) features a hollow grind. It has an extremely delicate edge, but it doesn’t need a durable edge due to its use. A hollow grind means metal is only removed at the secondary cutting edge, as well as at the spine to a lesser degree.

As a hollow grind assumes the shape of the outer diameter of the grinding wheel that sharpened it, different diameters of wheel will produce a less or more hollow grind. In other words, a large wheel creates an extremely shallow hollow grind while a small wheel creates a more prominent hollow grind.

If you are interested in trying to create a hollow grind in your own knife you should check out this calculator that allows you to put in the diameter of the wheel you are sharpening on and the thickness of your material to get the exact height of the grind to make a perfect hollow ground edge.

WARNING: If you sharpen your hollow ground knife on a sharpening stone, it will create a flat grind blade if done incorrectly.

If your kitchen knife has indentations on both sides, called scallops, that release the vacuum formed when cutting food and allow it to slide off the blade easily.

I recommend that you sharpen it with a good sharpening system or sharpening stone specifically for the grind on that blade or else you could ruin your knife.

Is the hollow grind right for you?

To wrap up, different jobs require different blade grinds. If you’re trying to pick out a blade grind, consider what it’ll be used for most to know which knife grind will suit your needs best.